well, ok, this is gonna take a minute ... loyal readers might think that since i haven't posted many new projects lately, that not much has been happening. they would be wrong. it's summer, and there is more going on at dorset custom furniture now than there has been for, literally, years. lots of projects in the works, on the board and committed, and in the design stage. i'm thinking that maybe this time it's for real, that the economy is finally rebounding, though i have been fooled several times in the last few years. cautious optimism creeps in ... click the photos to enlarge them ...

the kitchen we started back in may is slowly getting finished ... we're on the home stretch, and the painters have taken over now .. here are a few progress shots, the last being from wednesday, the third.

we've got a little cornice work, and some pantry pullouts to construct and then we put it all back together when the paint is done and the appliances arrive ...

it's starting to look like the model ..

next up on that project is a nice 8' x 8' master bath vanity, again painted. this is an early elevation that has since been revised.

this is the inspiration photo, with notes ...

we made the round corners and the main drawer box on tuesday and we'll be assembling the rest of the boxes later next week.

saw it, plane it, sand it ...

lots of parts to this project .. two other interesting vanities ...

this one in reclaimed barnboards, with their original, exterior texture intact ...

and some unusual corner shelves involving a hand hewn beam salvaged from the restoration process and some 3" thick torsion box shelves to fill the notches in the beam that were formerly occupied by the floor joists ..

plan view

above is the cardboard mockup, with some assorted door frames ... it's a busy site

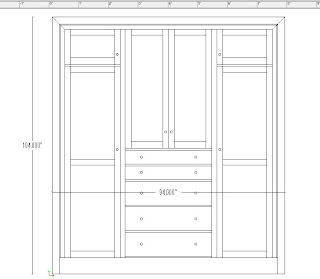

and for the same builder, on a different project, we're going to get to do a slightly smaller, 8' version of this 10' cherry shaker style wall piece we did back in 2006, in the same house .. it'll be old home days ..

and sam's busy in the metal shop .. working on some new railings for the dorset church ..

there will be a nice handrail and some forged scrolly things .. more on that later ..

he is finishing up a couple more steel lounge chairs for a landgrove client, and we've got 3 or 4 more steel and wood furniture pieces on the board ... coffee tables, two dining tables ... i just noticed a couple sections of recently completed railings in the background of this photo .. and so it goes ...

and will's off to west virginia for next week to take an instrument repair course with bob smakula ... in the near future, he's intending to really focus on his banjo business and see where that goes. banjo, i think, #17, above. cocobolo and brass, fretless .. cherry and walnut neck and pot ... more info on will's banjos at seedersinstruments.com

and, weather permitting, which lately we certainly can't guarantee around here, we'll be having some walls for the new metal shop. drawings are finalized, windows are ordered, used slate has been purchased ... it's all good. but did i mention the tropical monsoons we have been having here in vermont? like clockwork, most afternoons we're getting an inch or so of fresh rain daily and it's supposed to be 90+ degrees again today. sam's backyard trout stream is running at 10 times its typical cubic feet per minute for this time of year. ten times its typical july flow, i said. blown out, is, i believe, the term.

walls monday ...